The demining machine called DIGGER D-250, which will soon go to minefields, has an amazing story behind it. It was created thanks to the passionate desire of just one person who, above all else, strives to clear the land of mines. That person is Frederic Guerne, an engineer who started the project without money or a team but only with an idea and an unwavering determination to bring it to life.

His passion ignited others, and they became a team of young people, including even 14-year-old teenagers, who worked on the project voluntarily for four years. From the very beginning, it was purely a volunteer project.

The first machine, DIGGER D-1, was built in a small garage and went to work in Kosovo. Then there were three more generations of machines that managed to operate in 16 countries, clearing them of the remnants of war because mines are a war that remains on the ground even when the hostilities cease, bringing death and devastation.

Frederic's story is about how one person can do incredible things that can change the world. And we are happy that DestiNations.ua can share it with you.

"Our story is a bit unusual," says Frederic at the beginning of the conversation. "The Digger Foundation was founded in a garage, like in all those success stories from the USA. And it continues in a place that used to be a military arsenal. They used to store ammunition and weapons here, but now we are building a machine for clearing minefields."

Yes, it's symbolic. I read that in 1996 you were invited to a project, and when it ended, you decided to continue independently. Tell us, how did it all start?

I joined a demining project while studying at the Polytechnic University of Lausanne. However, the project ended after two years because it was a two-year program. But I decided to continue. I had contacts with deminers, and they approached me with various requests. And the first request was about this very machine. At that time, I was a young engineer working as a simple developer at a factory. But a familiar deminer approached me and said, "I know you're an engineer. Our team faces certain problems in Sarajevo: when we clear the fields of mines, we remove a lot of vegetation because it hinders the search for mines. And there are wire traps in the grass and bushes. These small wires, almost invisible, are connected to the mines. If you touch them, the mine explodes, and it's very, very dangerous. So, could you, as an engineer, create some kind of remote-controlled grass-cutting machine? One that would ensure no harm if a mine explodes. This machine should be well protected to withstand a small explosion and be able to cut vegetation and even trees."

.jpg) DIGGER D-250 (D-4) Bosnia, usage of rear backhoe at task

DIGGER D-250 (D-4) Bosnia, usage of rear backhoe at task

I am an electronics engineer, so I immediately said, "Yes, no problem."

I didn't have a team or money. I only had a lot of ideas. I shared them with everyone around me, and as a result, many people approached me and offered to help for free. It was purely a volunteer project. All these people were very young, ranging from 14 to 30 years old. Engineers, people from agriculture, and just young individuals. It was simply incredible. We started looking for a space to build the machine and found a garage. Then we found a welding system and quickly began working. Representatives of the media visited us and wrote something like, "Here is a crazy team building a demining machine with people aged 14 to 30." And then, we received our first donation. People gave us 30 francs each and said, "What you are doing is crazy."

When we received the first funds, we immediately bought a small engine, and the work continued.

However, I initially planned for six months of work with a budget of 17,000 francs. In reality, we worked for four years and spent 250,000 francs without paying anyone a salary.

Working for four years without payment?! Why? Did you have such internal ambition? A mission?

Yes, indeed. I worked 15 hours a day for five years, even at night and on weekends. I hardly saw my children and wife. My health deteriorated, and I ended up in the hospital... It was a bit foolish. But the whole team worked like that because we wanted to do something worthwhile. You know, we had many people from agriculture on our team. They couldn't accept the fact that there were unused fields in the world due to landmines. They said, "No, no, no, we can't accept that," and they worked with us as volunteers. We all just wanted to do something.

But the landmine problem doesn't exist in Switzerland.

Yes, we don't have landmines in Switzerland.

Where did your first machine start working?

The first mission was in Kosovo. As you may remember, the first deminers approached me regarding Sarajevo. But we got a bit delayed, and the project there ended. However, the landmine problem didn't go away. So the machine went to Kosovo.

The first task for our machine was a field near the incredible Olympic Stadium in Sarajevo. And it completely cleared it. Currently, we have two of our machines working in Bosnia. My colleague is there right now, tuning up the oldest machine operating in the field. It's the same vegetation-cutting machine. It's small, weighing 4 tons. We call it "Peanut." That's our Digger 1.

And then the same familiar deminer returned and said, "Well, your vegetation-cutting machine is very good, but now we have a minefield in South Sudan, and we need a machine to dig the ground and detonate the mines because it's much more efficient. Can you modify the machine?" I said, "No problem." We didn't make much money with the first machine but won two awards. So people started paying more attention to us and providing more support. Therefore, after five years of work, I could finally hire one person—an engineer (not me, another engineer)—and we left our small garage and moved to a former military arsenal. Then we hired another person, and in the end, we formed a "huge" team of five people. And then we built the second machine.

What was the main motivation for continuing the work? Were there periods when you felt stressed, depressed, and wanted to stop and leave it?

Yes, it was challenging. I became seriously ill and burned out. But something important motivated me. When I traveled to these countries, met people, and saw what was happening, I told myself, "We can do something." You see, when I can do something effective, I can't not do it. It's my faith, my calling, my mission - all together. I can't just "work for the watchmaker"; I'll die if I do that. Even working in the industry, I could never earn a good salary. That didn't interest me at all. I'm not a businessman at all. When I was first hired as an engineer at a factory, a guy asked, "Well, how much do you want?" When I stated the amount, he replied, "No, that won't be enough for you." So I said, "Okay, then 4000 will be enough." "No, overall, you'll need more," he answered. I'm terrible at negotiations, you know.

DIGGER D-250 (D-4) in Angola

DIGGER D-250 (D-4) in Angola

What was the second machine-like, and where did it work?

Frederic: We built the second machine for South Sudan. It's much bigger than the first one - weighing seven tons, and its engine is twice as powerful. And it can dig the ground. Initially, this machine worked in South Sudan's south and north. They were still one country at that time. During the war, the borders were mined, and many people fled to Ethiopia as refugees. And all these people couldn't return even after the war ended. With the help of our machine, part of the border minefields were cleared, and we saw thousands of people returning home. You see, this machine changed the lives of thousands of people. And for me, it was very important. When we destroyed the first real mine in the field, I said we probably saved one person's life. It was the most beautiful gift I have ever received in my life. It restored our motivation. However, it took us seven years for that.

Today, we have 12 people working full-time. We are still a very small company. Currently, we are collaborating with Ukraine and had to hire people because we need more machines.

How much time does it take to produce one machine?

Frederic: We spend one year on one machine. And it's tough to comprehend because currently, around 60 countries in the world are contaminated with landmines. However, the funds provided to support these countries are very limited. We are often told, "We can't buy a machine. Even though we support this country, we don't have the money." But when the machine is operational, it clears one square meter ten times cheaper than doing it manually. However, initial investment is required, and the willingness to invest is not a characteristic trait of humanitarian organizations. Humanitarian work is about doing a small task and a lot of advertising. It's harsh to say, but it's often the truth. Investing in a vital machine is not part of their work.

Digger Foundation is a non-profit organization. As a non-profit organization, we have access to certain donors, funds, and federal cantons and develop projects. We are not deminers ourselves; we simply collaborate with people engaged in demining on-site, and these people work manually, as is currently being done in Ukraine, which is terrible. To provide them with a machine, we have to jointly develop a project to determine who will do it, which populated areas will be cleared, and what the results will be. In other words, we don't just have a machine. We have a project. And when 12 people work on it, who both build the machine and develop the project, it takes a long time because it's a big job. Therefore, we can only make one machine per year.

How much does one machine cost?

Approximately 700,000 CHF.

What area can this machine clear, for example, in one year?

The machine can clear a football field in 3-8 hours. A manual deminer would take 1-3 years to do the same.

That's fast.

And safe, but it needs to be appropriately used, so we train people not only to operate the machine but also to educate them on how and where it can be used, as well as its limitations.

We already have four generations of machines. DIGGER D-4 is the most powerful. We call it DIGGER D-250. It has a power output of 250 horsepower. It weighs 12 tons and can even handle anti-tank mines, destroying up to 8 kg of TNT mine. Of course, it's not designed for all anti-tank mines, but if you have one in your field, our machine can handle it. It was accredited by the world's only qualified testing center that conducts accreditation of humanitarian demining machines following norms and standards. This is a highly professional machine.

.jpg) DIGGER D-250 (D-4) withstanding 5.5kg TNT exposion

DIGGER D-250 (D-4) withstanding 5.5kg TNT exposion

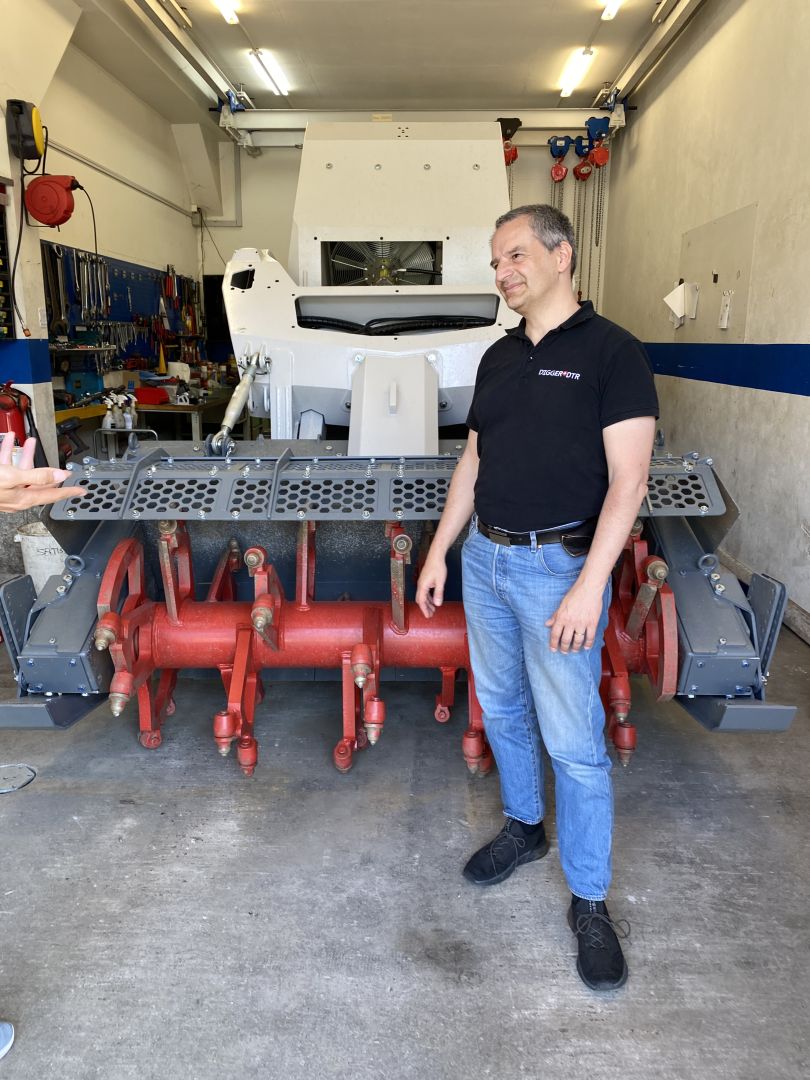

Where will this DIGGER D-4 in front of us operate?

It's heading to Angola, and we continue to work on the rest. This machine is funded by the Canton of Bern and some private donors specifically for a humanitarian demining organization in Angola.

What are your plans for Ukraine?

We are preparing two machines for Ukraine. Currently, one is almost ready (while the material was being prepared, the first machine has already been sent to Ukraine (editor's note)). And we are working on the second one and waiting for the contract from the donor.

And who is the donor?

The Swiss government.

Tell me a bit more about DIGGER D-4.

Frederic: It has a tractor engine, 250 horsepower, and hydraulic transmission. We don't build the engine; we buy it. We also purchase the tracks. But everything else we do ourselves. We also have our own electronic and software computer system.

Is it operated remotely?

Always! Our philosophy is to keep people away from danger. I would like to note that our machine is not very environmentally friendly because it burns about 40-45 liters of fuel per hour. It has a good filtration system but is still not environmentally friendly. However, mines are also a form of pollution.

What prospects for development do you currently see?

Due to the needs of Ukraine, we even took the risk and hired a few more people. But I have a dream - to create a company, a production line near Kyiv. That's the main project I'm currently working on. Over a year ago, almost from the beginning of the war, I contacted the Swiss ambassador in Kyiv, and even then, he clearly understood the situation. He mentioned seeing minefields before in Donbas and acknowledged the significant need for demining. Since Ukraine has many technical capabilities, skilled professionals, and great know-how, this dream project can be realized. Together with the ambassador, we immediately started looking for a company that would align with our thinking and values. I don't want to work with a company that manufactures weapons, for example. I also need a small company that is already engaged in humanitarian work. And the ambassador found such a company, SHERP vehicles, built by Quadro International LLC. Quadro International creates small vehicles that can float on water. The UN uses them to deliver food to hard-to-reach places. We have already signed a joint agreement and are working on establishing this partnership. My dream is to have Ukrainian workers who will manufacture our machines under license in Ukraine. And now I'm trying to get support from the Swiss government to make it happen. But it's quite challenging. You know, the Swiss administration is, how to say... prudent, and taking risks in such a project is complicated.

Does it oppress you?

It's tough when you see all these publications and discussions in the media, but you realize that we're doing very little. But I hope to do something in your country. As soon as possible. Your Minister of Economy officially stated that we need 100 such machines and specifically mentioned the need for production in Ukraine. It's just incredible for us. Your Prime Minister also knows about us. So we have to establish production together with people from your country.

Yes, we have many engineers.

Working together is something I genuinely dream of. Sometime your Prime Minister said, "Our economy is suffering. The war really affects it. Please support our economy as well. Humanitarian support is important, but support our economy because the war is a big problem." And it's for this reason that we started this program because we can do two things simultaneously - support the economy and clear territories of mines.

It's a very ambitious and important goal, and we believe it will be achieved. Thank you for all your efforts.

We thank the embassy of Switzerland in Ukraine for the information provided.

Images provided by Digger Foundation.