Our focus is on a unique technology of Finnish origin, which has been successfully used in the world market for more than 30 years. Holly Industrial has been working in Ukraine since 2012. And it is the official exclusive licensee of URETEK. These technologies have no competitors in the world, but there are competitive solutions – and these are old solutions: dig a hole in the ground and strengthen it with concrete, which is not always effective at all. Unfortunately, the technology of construction is often violated in Ukraine and as a result, foundations subside.

Read: Agribusiness Potential: Expert Estimates

Oleg Katiushchenko: Essentially, we are working with all the structures that are in the ground. These can be reinforced concrete or stone structures, rubble foundations, which were built, for example, back in the 17th-18th centuries. By the way, I am going abroad tomorrow to inspect a site. It is too early to give any details. I do not want to jinx it. But it is a world famous cathedral. You heard about it (Smiling).

If we narrow the range of your work down to agriculture?

We work with all reinforced concrete structures that are used in agriculture. These can be various elevator facilities and the entire infrastructure around them, for example: elevator towers, lifts and drying towers. They stand on huge foundations which sometimes subside. Of course, these can be any other facility – dairy and livestock farms, warehouses and so on. If we consider our proposal for elevator complexes, this is about 10% of silos which are already tilting and only half-loaded.

What technologies does URETEK offer and what is so special about them?

We work in two areas: Slab Lifting and Deep Injection.

1) Slab Lifting includes supporting any slabs and flat reinforced concrete structures that are in the ground or on the ground, or on some prepared base. If a concrete floor slab has slipped or cracked – this can happen if the design was incorrect, slabs are insufficiently thick, the load is too heavy, or the soil has decompressed beneath it. As for agriculture, these can be slabs of warehouses where a precise horizontal surface is critical.

Read: Big Change in Agrarian Technologies

If we are talking about elevators, inside each tower there is a plate, with ventilation ducts, through which air is supplied under pressure from below. It goes through the grids upwards, passing through grain, ventilating and drying it. But these slabs often subside covering ventilation ducts, grain becomes damp and decomposes. We prevent these processes: we get everything to the level and lift it back with an accuracy of 1 mm.

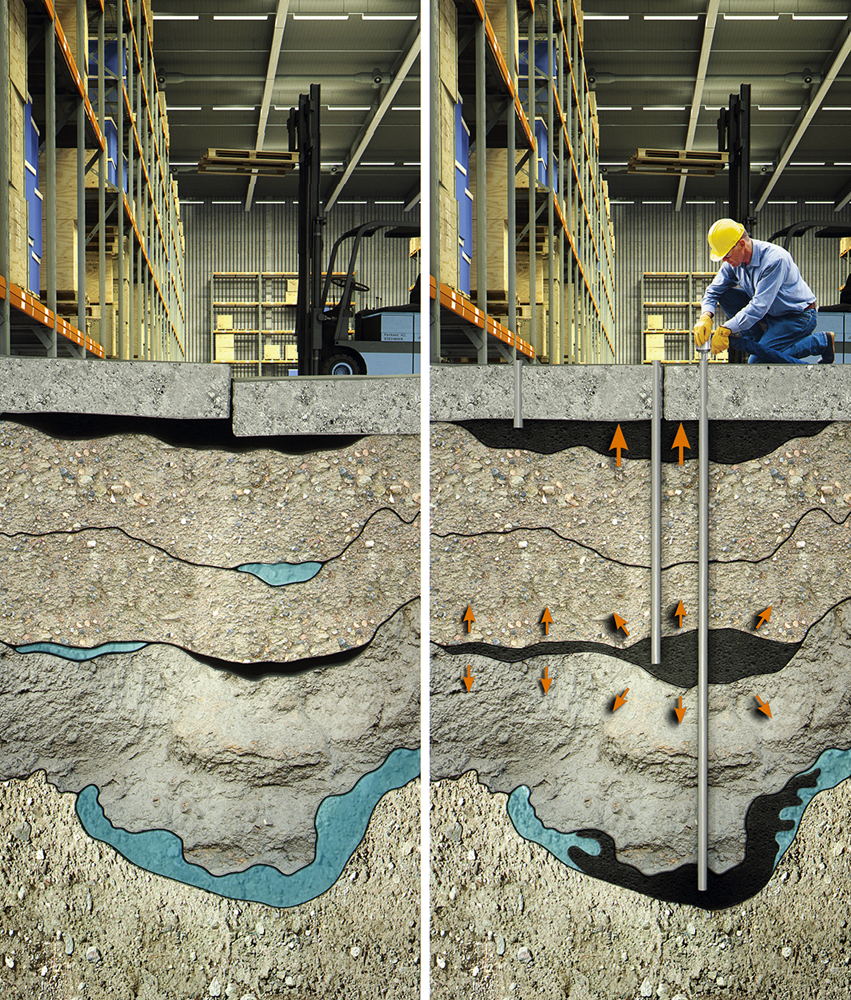

Image: Deep injection technology

2) Deep Injection is done to any reinforced concrete foundations that are in the ground. In this case, we work directly with foundations. For example, with the foundations of an entire elevator complex. If, due to various anthropogenic reasons, for example, soil was poorly protected from getting wet, water leaked into the ground, the foundation got damp and the structure started subsiding one way or another, the tower starts to move along the vertical axis and the system is damaged. There is eccentricity. I know that some large elevator complexes in Ukraine cannot work to capacity for this reason. Thus, the owners do not receive what they are due. And we can fix it all. We already have a lot of success stories in our portfolio.

Tell us about the competitive advantages of these technologies.

We do top-quality job and do it very fast! (Smiling). With URETEK technologies you need no ground works or excavation. For example, in the case of an elevator complex, we repair a "bin" after "bin" for a week, 10 days at most. That is, while we are restoring one of them, all the others, even those close to it, can work uninterrupted.

We practically do a "by-pass surgery" (high accuracy of work) by drilling narrow holes (14 mm), inserting a special tube and injecting resin. We do the high-quality job and leave the place neat and beautiful. (Smiling)

There is a 10-year warranty on what we do. But if a structure behaves well during a year, then it is going to stand for 20 or 50 years more. The estimated service life of URETEK materials is at least 50 years or more. Current tests confirm that the actual estimated life of the material is much longer than this period. With its hydrophobic properties and high adhesion, our material is highly waterproof. But these are related properties. And our solutions are environmentally friendly! Our materials do not pollute the environment.

Read: Eco Gourmet Restaurants in Kyiv

How expensive is it to "prolong the life" of an elevator with the help of your technology, and how soon will this modernization pay off?

We did such calculations. Let us assume the current loading of a complex is, for example, 50%, then investment in reconstruction will pay back in 2-3 years. We are talking about investment not in construction, but in "rehabilitation". However, this is an average indicator. Everything depends on the condition of a facility in need of such a solution.

Fundamental Solutions in Agribusiness

Holly Industrial Company exclusively represents URETEK technologies in Ukraine. They are used to stabilize foundations and lift slabs. The company's founder and director-general, Oleg Katiushchenko talks about the unique technology and its competitive advantages.